DAYE Profile

ABOUT DAYE

We are a diecast supplier which established in 2002, and specializes in aluminum alloy/zinc alloy die-casting. We have advanced diecasting technology and CNC machining equipment, capable of designing and manufacturing accessories as well as finished products. We provide full services including products research and development, mold design and manufacturing, die-casting, precision machining, surface treatment and finished product assembly for customers in various indurstries, such as furniture, household appliances, lighting and automotive.

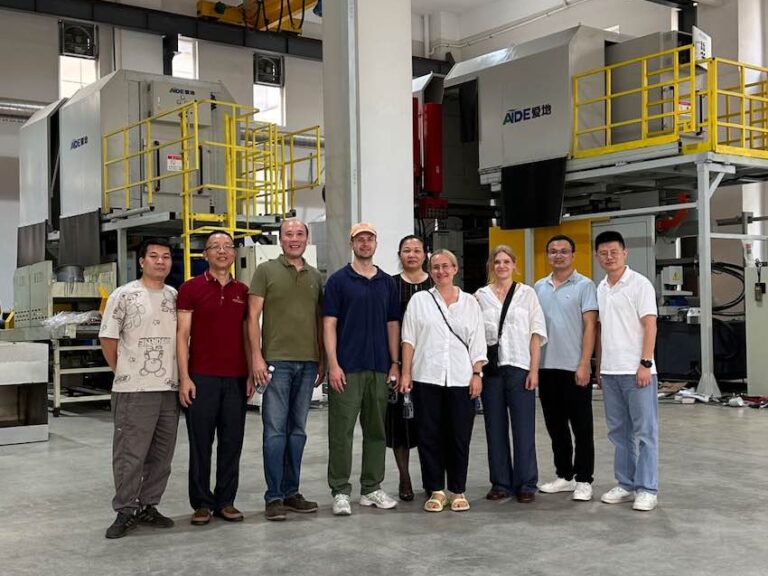

We are based in Foshan city, China, where the furniture and household appliances industries cluster. Our annual output of aluminum/zinc alloy die castings has reached 2,000 tons. Everyday we develop and manufacture die-casting products for customers around Italy, Denmark, Germany, Japan, the United States, Southeast Asia and mainland China.

DAYE STORY

Yaofeng Liang founded DAYE Diecasting and started producing household appliance accessories for Sanyei Corporation of Japan.

Start-up of household appliance components production for Vanward, Midea and Glanz of China.

Start-up of furniture accessories production for B&B Italia.

Obtained ISO9001 certification.

Started collaboration with Nine United Group of Denmark, producing furniture accessories for its sub-brand Hay.

Collaboreted with DEDON of Germany, Toshiba of Japan and Gloster of Switzerland to develop furniture accessories such as chair foot, chair base, meeting table, etc.

Continued OEM of furniture and household finished products. At the same time, the company has formed scale production of household appliances accessories and furniture accessories.

Energy consumption upgrade.

DAYE factory replaces diesel and carbon with electricity as the main energy consumption, taking an important step towards environmental protection.

Developed series of finished products with furniture brands, completing a major leap from the production of accessories to the production of finished product.

Obtained FSC forest management certification.

Honors & Certifications

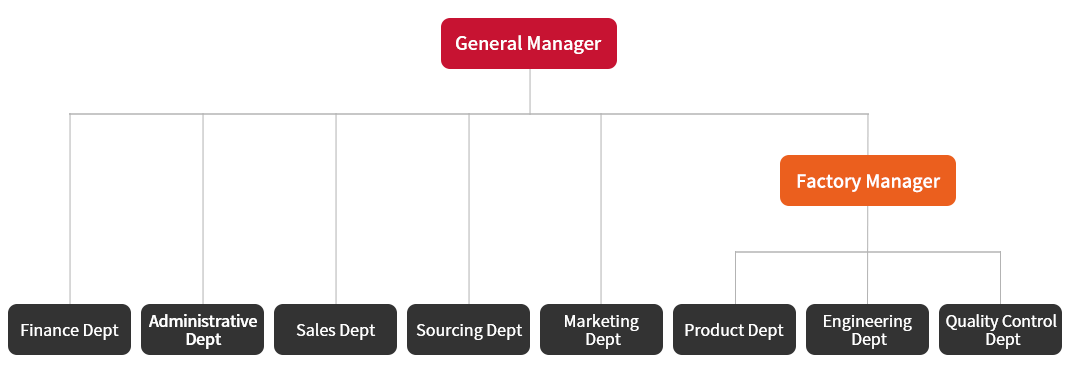

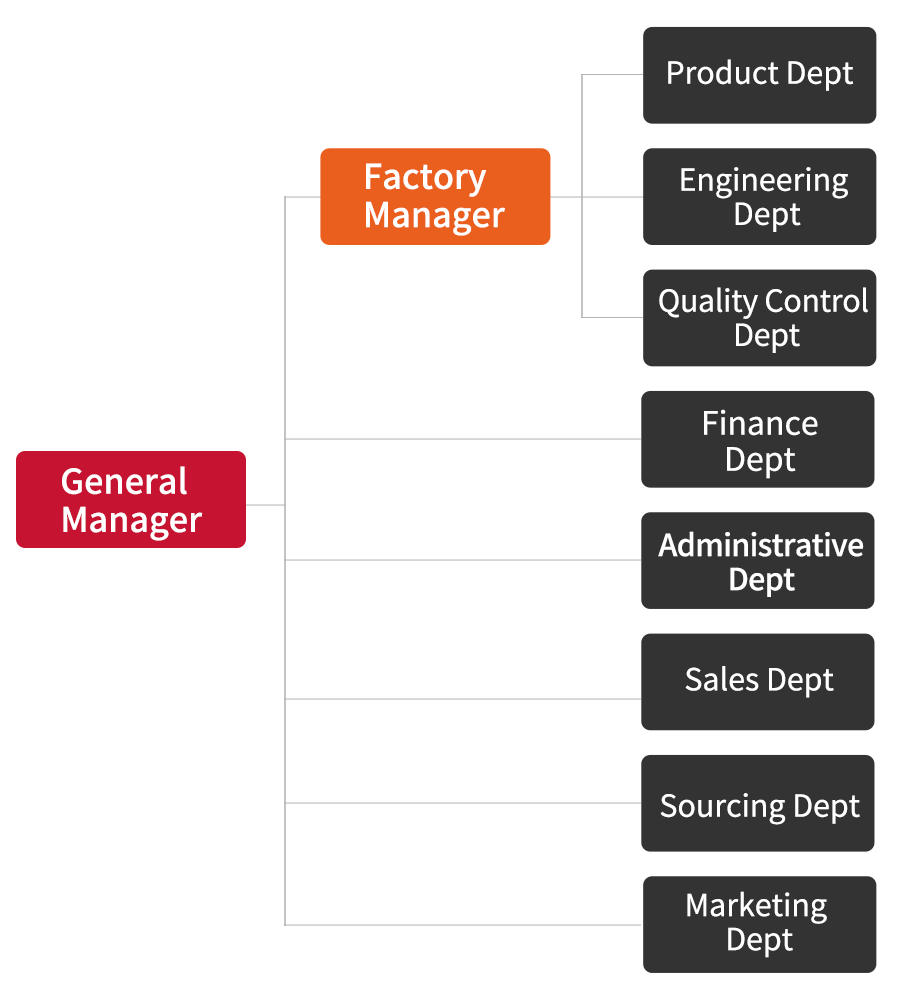

Organizational Structure