Evaluating the appropriate manufacturing process you can utilize to design an aluminum component is very importance. Many common yet popular processes are available for aluminum forming, but one of the most common ones that most designers consider is aluminum die casting.

In the realm of automotive, industrial, and telecommunications products, aluminum die casting is a favored technique employed by experts. This method is also frequently utilized in the creation of electrical, hydraulic, lighting, and furniture components.

In essence, a metal-forming process of designing intricate aluminum components is known as aluminum die casting. This involves heating aluminum alloy ingots to extremely high temperatures until they become completely molten. Subsequently, under high pressure, a liquid aluminum called a mold is inserted into the hole of the steel die. Because the die is made up of two halves, the solidified molten aluminum gets separated and displays the cast aluminum part. The product typically exhibits a soft texture and requires minimal or no machining. The method can be repeated multiple times, utilizing the ultimate mold until it deteriorates, making aluminum die casting pertinent for the enormous production of aluminum parts.

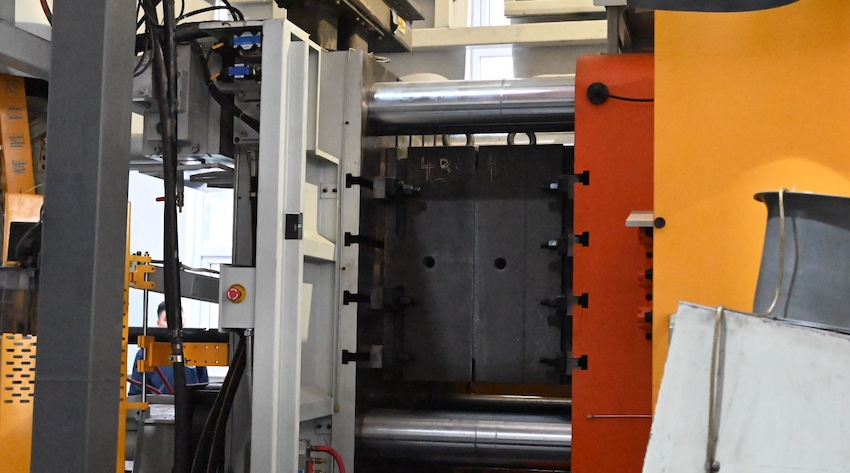

The aluminum die casting machine is working in DAYE factory.

ALUMINUM DIE-CASTING ADVANTAGES

Aluminum casting offers a range of surface finish options. One notable advantage of the aluminum die casting process is its dimensional stability. Additionally, aluminum castings are highly versatile and in demand across various industries.

Here are some key benefits of aluminum casting:

- Finished productions with exceptional surface finish

- Exemplary tensile strength

- Cost-effective raw materials

- Minimizing Impurities and Porosity

- The molecular structure ensures dimensional tolerance without any damages

- Durability

- Thickness precision (thickness less than 1.5 is achievable)

- Airtightness and pressure resistance

- Multiple alloy options with varied chemical and mechanical properties

- Can produce parts with very complex designs

DAYE produces various automotive components of complex structure.

PICKING AN ALLOY FOR APPLICATION

The utilization of aluminum in casting offers a significant advantage, which is the capability to define the essential properties. Despite the project and specific application, there is always an appropriate aluminum alloy die casting solution available. Hence for a better decision, it is crucial to pick the appropriate alloy based on the required characteristics.

Please find below a list of the essential properties and characteristics to choose the type of alloy for an application.

- Corrosion Resistance – only changes when alloyed but perfect in its natural state

- Strength – estimated by temper, tensile strength, and yield

- Heat Treating: reduce chemical segregation and improve workability

- Formability – the ability to experience plastic deformation

- Weldability – solidification shrinkage, thermal conductivity, oxide coating, hydrogen solubility

- Machining – bendability, able to be drilled, resistant to low temperatures

Aluminum can be repeatedly recycled without a decline in materials performance or quality.

CHARACTERISTICS OF ALUMINUM DIE CASTING ALLOY

The aluminum alloy contains numerous advanced chemical and mechanical characteristics. Notably, they are corrosion-resistant and have increased heat dissipation capabilities. Additionally, its strength-to-weight ratio is highly advantageous. These attributes enable mechanical engineers to create aluminum die casting parts with unparalleled versatility.

There are additional properties:

- No much weight

- Corrosion-resistant

- Better strength-to-weight ratio

- High operating temperatures

- Adequate stiffness

- Good finishing characteristics

- RFI and EMI shielding

- Outstanding thermal conductivity

- Increased electrical conductivity

- Complete recyclability

APPLICATIONS OF ALUMINUM DIE CASTING

Given its weightlessness, strength, and resistance to corrosion, aluminum stands out as an optimal material for creating durable and trustworthy system components. Furthermore, its economic benefits and mechanical attributes make it the ideal choice for diverse applications and industries.

AUTOMOTIVE INDUSTRY

The automotive industry finds aluminum die casting ideal to use due to properties such as durability and lightweight compared to steel and iron. Moreover, its lightweight feature makes it an optimal selection for transportable applications.

INDUSTRIAL EQUIPMENT

Aluminum die castings are extensively utilized in the industrial machinery and equipment industry for various components of equipment and systems. For example, die-cast equipment components cover connecting rods, bearings, and pistons.

CONSUMER PRODUCTS INDUSTRY

Aluminum die castings are employed in the consumer products industry, contributing to the creation of robust and lightweight final products.

RECREATIONAL VEHICLE

The aluminum die casting process helps produce many recreational equipment and vehicle components within the recreational equipment industry. This includes structural and functional elements such as axles, chassis, counter mounts, and cosmetic components like hood ornaments.

RENEWABLE ENERGY

In certain sectors, aluminum die casting is employed for the production of power generation and distribution equipment in the renewable energy industry. Some examples include:

- solar panel brackets

- wind turbine parts, etc.

AEROSPACE

In the aerospace industry, there is a need for components that can deliver up-to-the-mark performance. Aluminum die castings are particularly suitable for aircraft due to their lightweight nature, high durability, and cost-effectiveness. They can withstand severe operational and environmental conditions, and have better fuel efficiency.

AGRICULTURE SECTOR

Die-cast aluminum components can be utilized in various agricultural machinery, including combine harvesters and tractors. This material is the best for these demanding applications due to its durability and reliability.

MEDICAL INDUSTRY

Aluminum die-cast components are prevalent in various devices and systems within the medical industry. From diagnostic and treatment equipment to hospital beds and surgical tools, such productions are integrated into nearly every aspect.